ZTE Corporation, a global leading provider of ICT solutions, has piloted an AI industrial-quality inspection system with China Mobile and Changzhou Xingqi Technology. This effort uses Cloud SPN computing and network convergence to deliver cost-effective edge computing capacity to help industrial businesses shift into digital and intelligent production.

Addressing Quality Inspection in Traditional Industrial Parks

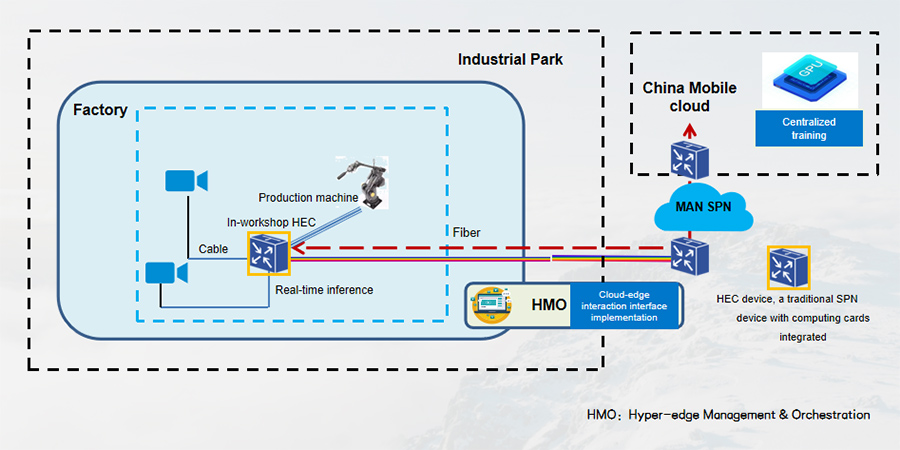

Quality inspection can be challenging in traditional industrial parks. China Mobile and ZTE developed the Cloud SPN computing and network convergence solution to address these issues. The technology employs native HEC (Hyper-Edge Computing) at the access layer in the existing SPN to supply the local computing resource pool. The edge-cloud synergy solution combines edge computing, cloud computing, and network capabilities to deliver slicing private line and AI computing services tailored for the ToB vertical industry. This facilitates swift deployment of AI applications in industrial parks.

In early 2022, China Mobile Jiangsu Branch and China Mobile Changzhou Branch jointly explored Cloud SPN computing and network convergence technologies with guidance from China Mobile and China Mobile Research Institute. Verifying computer power deployment and application in the current network began in 2023.

The computer board-equipped access SPN device swiftly applies HEC to the access-layer SPN. To enhance collaboration among terminals, edges, and clouds, the industrial on-site network is equipped with a dedicated private line that incorporates native AI computing services. This method allows ubiquitous computer node deployment, flexible resource scheduling, simplified network hierarchy, lower power consumption and energy saving.

Xingqi implements an AI machine vision quality inspection application using ZTE's on-site HEC device (ZXCTN 6180H combined with computer boards) for the eighth station's spray code check. Because of this, quality inspection precision rose to 99.99%, inspection equipment investment dropped 75%, and local AI computing construction costs dropped over 90%.

Furthermore, the AI model-based industrial quality inspection procedure also allows order-based switching, enhancing sampling and inference efficiency five times —from 24 to 120 times per minute.

A successful two-year experiment proved the technological viability of slicing private line and AI computing service and pioneers hyper-edge computing and network convergence solutions. China Mobile, ZTE, and Xingqi have discovered commercial value-added business processes and services, enabling operators to switch from channel to ToB service operation.

A Revolutionary Partnership

The partnership between ZTE Corporation, China Mobile, and Changzhou Xingqi Technology introduces a pioneering AI industrial-quality inspection system. Leveraging ZTE's global expertise as a leading ICT solutions provider, this collaborative effort aims to revolutionize industrial processes. The integration of Cloud SPN computing, and network convergence stands out as a key highlight, offering a cost-effective solution for enhancing edge computing capacity. This technological advancement is poised to assist industrial businesses in transitioning towards digital and intelligent production methods.

Through the implementation of the AI industrial-quality inspection system, companies can achieve more efficient and precise quality control in their manufacturing processes. The strategic collaboration emphasizes the practical application of cutting-edge technologies to address real-world industrial challenges; showcasing the commitment of these industry leaders to drive innovation.

Furthermore, the partnership facilitates a seamless integration of AI into industrial operations, promoting a shift towards digitalization. By combining ZTE's ICT solutions with the network capabilities of China Mobile and the technological contributions of Changzhou Xingqi Technology, the collaboration empowers industrial businesses to embrace a more intelligent and connected future.